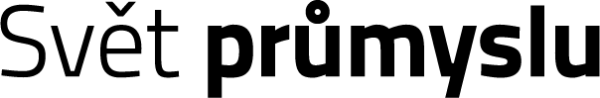

Orion’s third European Service Module (ESM-3) is leaving Airbus’ facilities in Bremen, Germany, and heading to NASA’s Kennedy Space Center in Florida, where it will be assembled and tested with the Crew Module. This third mission in NASA’s Artemis programme will mark the first human return to the lunar surface since Apollo 17 in 1972.

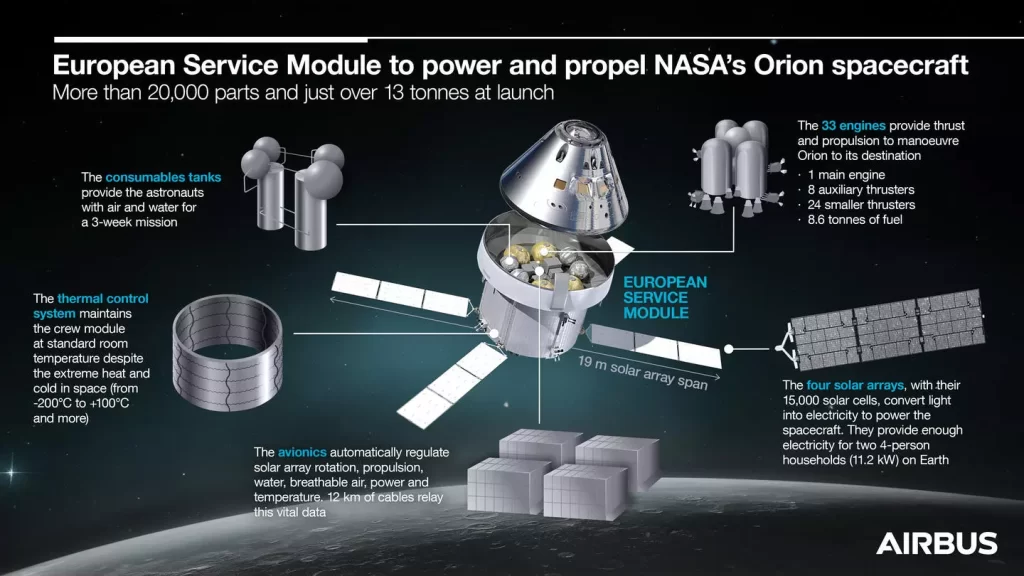

The ESM-3, built by Airbus under contract to the European Space Agency (ESA), will play a critical role in supporting four astronauts during their three-week mission aboard the Orion spacecraft: from the moment they leave Earth’s orbit, through their journey into lunar orbit, docking with the Human Landing System (HLS) in lunar orbit, and their safe return to Earth.

Regulating Orion’s temperature in space

Space is a harsh place, with temperatures as low as -200°C. The temperature inside the spacecraft has to be controlled to keep the astronauts comfortable and to ensure that all the equipment works optimally.

“To manage the temperature in the crew module and the ESM, we have developed a thermal control system,” explains Matthias Gronowski, Airbus Chief Engineer for Orion-ESM. The thermal dissipation generated by the astronauts and the equipment in the crew module is transferred to the ESM via the heat exchanger, which ensures that the thermal energy is radiated outside the spacecraft via the radiators. The temperature in the crew module is thus stabilised at standard room temperature, while the equipment temperature range inside the ESM is controlled for proper functioning, from 20 to 60°C.

The other means of keeping the temperature at the right level is multi-layer insulation (MLI), the white blanket that covers Orion and reflects the sun flux back into space. It prevents heat loss from inside to outside of the ESM, and protects the spacecraft from the external thermal environment.

Basic needs: breathing and drinking

Protection from heat and cold is one of the basic needs of astronauts. So are breathing and drinking water, and the ESM makes this possible.

To recreate an environment similar to Earth’s atmosphere inside the crew module and enable the astronauts to breathe, the ESM stores 30 kilogrammes of nitrogen and 90 kilogrammes of oxygen. “We need to create an atmosphere similar to the one on Earth, which means we need the right mix of nitrogen and oxygen in the cabin,” says Gronowski.

But nitrogen also plays another role onboard: it is used to pressurise the drinking water tanks to allow water distribution onboard. The ESM-3 carries the main source of drinking water for the astronauts, and features a 240-litre tank.

An all-electric spacecraft

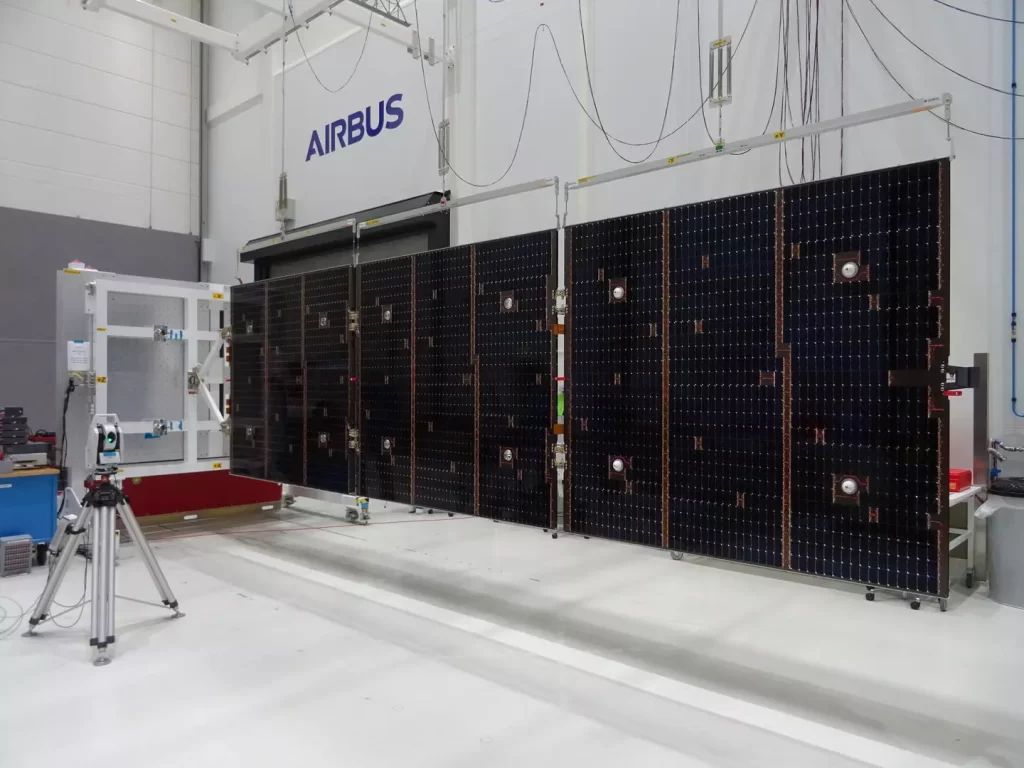

Unlike the Apollo missions, which used fuel cells to generate power, Orion uses only the sun. The four wings generate 11.2 kW of power, enough to power two four-person households on Earth. “Of that 11.2 kW, we use about 10% for the ESM components and the remaining 90% goes to the batteries and equipment in the crew module,” Gronowski explains. “The Artemis I mission highlighted that the solar panels were able to produce a bit more power than expected. It will be useful to have this additional energy available as the Artemis programme evolves.”

The energy stored in the crew module’s batteries is key. First, it ensures that the Orion spacecraft has power even during an eclipse. The batteries also provide power to the crew module after separation from the ESM at the end of the mission, at which point power from the solar panels is no longer available.

Avionics for a high level of automation

To enable astronauts to concentrate on the most important tasks, the avionics onboard provide a very high level of autonomous capabilities, such as temperature regulation or solar array rotation to track the sun. “In principle, the whole spacecraft can fly the mission completely autonomously, but compared to the uncrewed Artemis I mission, Artemis III will enable the astronauts to dock manually with the Human Landing System,” says Gronowski.

33 engines for a unique mission

Once the Orion spacecraft has separated from the launcher, it will rely on the 33 engines onboard the ESM to provide thrust and manoeuvre Orion to its destination. There are three different types of engines in use.

The main engine, a repurposed Shuttle orbital manoeuvering engine (OMSE) provided by NASA, generates 26.5 kilonewtons of thrust, which is enough to lift a van. This provides the kinetic energy to escape Low Earth Orbit and perform the translunar injection burn, a manoeuvre that accelerates the spacecraft and puts it on its trajectory to the Moon. Eight auxiliary thrusters act as back-ups for the OMSE and provide trajectory corrections. Lastly, twenty-four smaller engines provide attitude control for manoeuvring in space, allowing the spacecraft to perform specific manoeuvres like docking.

“All 33 engines receive the same propellant from the same tanks via different diameters of tubes, using a helium pressurisation system,” says Gronowski.

ESM is a very complex piece of engineering to design and assemble, with a lot of individual hardware and subsystems that must meet strict requirements. With more than 100 Airbus team members working on the different sections, it is a real collective achievement. “Contributing to humanity’s return to the Moon and being part of this historic moment is a huge source of pride for all the European Airbus teams and the supply chain,” concludes Gronowski.