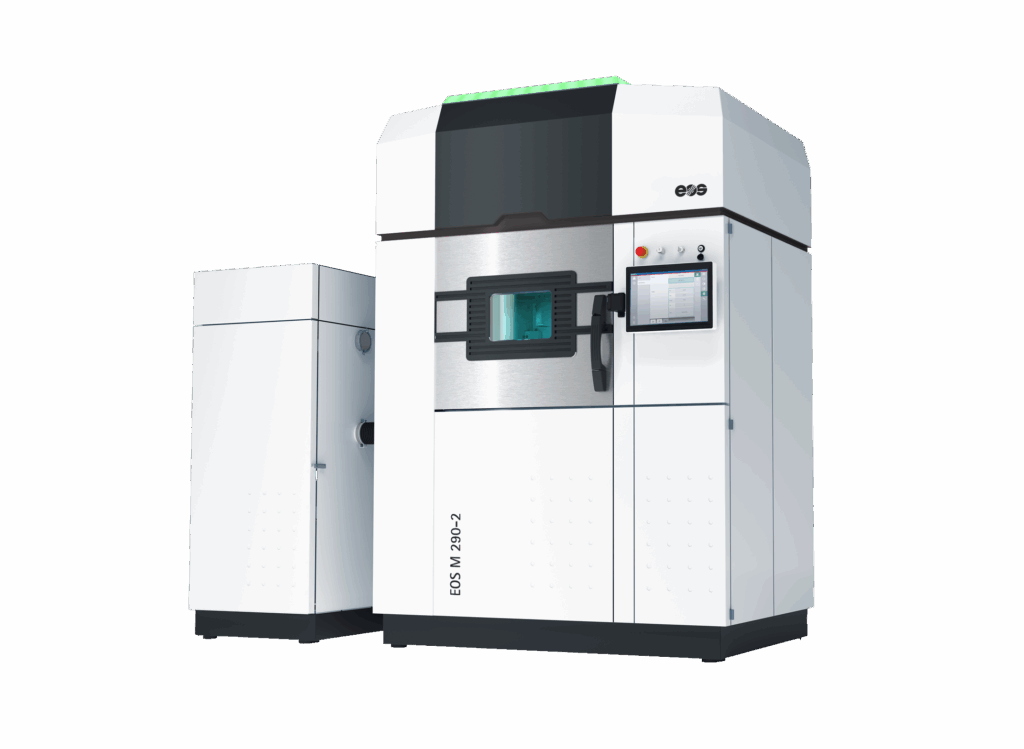

Dr.-Ing. Tina Schlingmann serves as Market Engagement Officer for the EMEA region at EOS GmbH, a global leader in industrial 3D printing. In this interview, made possible through a partnership with Future Port Youth, she shares insights from her journey in materials research, lightweight design, and decentralized production. She reflects on how additive manufacturing has evolved from prototyping to full-scale production, how it supports sustainability, and why openness, collaboration, and courage are essential for the next generation shaping the future of technology.

Your background is deeply rooted in materials science and additive manufacturing. What first drew you to this field, and what continues to excite you about it today?

During my PhD, I worked on developing a high-strength aluminum alloy for the aerospace industry, mainly using traditional forging. It’s a reliable process, but pretty limited when it comes to design possibilities. The first time I saw what 3D printing could do, I was blown away — suddenly, almost any shape or idea could become real. That creative freedom and potential to rethink how we design and make things still excites me today.

At EOS you are driving innovation in industrial 3D printing across the EMEA region. What real-world impact do you see additive manufacturing having today, and what transformations do you foresee in the next 5 to 10 years?

Let me start this way: when I first came into contact with additive manufacturing about ten years ago, it was mainly used for rapid prototyping. Today, it’s already an essential part of many industries — from aerospace and medical to consumer products and even defense. It’s amazing to see how far the technology has come.

That said, in highly regulated industries there are still some qualification and certification hurdles to overcome. But I believe that in the next five to ten years, many of these barriers will be behind us. We’ll also see a much broader range of printable materials, which will unlock completely new opportunities for true serial production.

Source: Alphaform | EOS : Additive Manufactured patient-specific porous cranial mesh implant with optimal fit and permeability, supporting bone ingrowth and significantly improving patients’ quality of life.

Hydrogen-powered mobility, lightweight design and decentralised production are all trending topics. How do you see additive manufacturing enabling these trends, especially in terms of sustainability and scalability?

Additive manufacturing plays a key role in all these areas. Especially when it comes to lightweight design, the technology allows us to completely rethink how parts are created — making them more organic, more efficient, and ultimately more resource-saving. That directly contributes to sustainability.

We also see great examples of decentralized production already happening — for instance, European railway companies are using 3D printing to improve spare part availability. Instead of shipping physical parts around the world, they just send the digital file and print locally.

It’s exactly this mindset that aligns with EOS’s purpose of responsible manufacturing — using technology to make production smarter, more sustainable, and more adaptable.

You have worked across both industry and research. In your view, what are the keys to successful collaboration between the academic world and tech companies?

For me, the key to successful collaboration between academia and industry is strong networking and open communication. Of course, fundamental research is essential — and sometimes the best discoveries happen by accident. But from my experience, partnerships work best when research is driven by real industry needs and geared toward concrete applications. That’s when innovation moves from the lab into the real world and creates real impact.

Future Port Youth focuses on empowering the next generation. What skills or mindsets do you believe are essential for young people who want to shape the future of technology and industry?

I wish every young person to approach the world with open eyes and constant curiosity. Stay curious, ask questions, and don’t be afraid to step outside your comfort zone. Talk to people, exchange ideas, and try to see things from different perspectives.

Very often, the most creative ideas and breakthrough innovations come when people from completely different backgrounds and disciplines start collaborating and learning from each other. That openness — both in mindset and communication — is, I believe, the real key to shaping the future.

Many students and young professionals admire innovation leaders but do not know where to start. What advice would you give to someone who wants to get involved in advanced technologies but might feel intimidated or unsure of their path?

It’s completely normal to feel unsure at the beginning — everyone starts there. My advice would be: don’t wait until you feel “ready.” Just start exploring. Try things out, take small steps, and stay open to learning along the way.

Building your own network can make a huge difference — connect with people who inspire you and don’t hesitate to reach out for advice. Finding role models can also be incredibly helpful. I personally support several mentoring initiatives, especially for women in STEM at Technical University Berlin, because I truly believe that seeing someone who’s walked the path before you can be a powerful motivator.

Technology and innovation aren’t just about technical skills — they’re also about curiosity, creativity, and collaboration. Surround yourself with people who share your passion, keep asking questions, and remember: every experience, even the failures, helps you grow and find your direction.

As a woman in STEM and a senior leader, have you encountered any particular challenges, and what lessons have you learned that could inspire others on a similar path?

That’s a big question — I could probably talk about it all evening. But if I had to sum up the most important lessons, I’d say: find your allies, look for role models, and build a network of people you can trust and learn from. Stay curious, follow your passion, and don’t be afraid to ask for help when you need it — no one succeeds entirely on their own.

In my own career, especially in the early years as a woman in a male-dominated field, I had a coach who supported me through many challenges. That experience taught me how valuable it is to have someone who helps you reflect, grow, and stay confident.

Ultimately, I believe you’re usually best at what you truly love doing — so find what excites you, and let that guide your path.

Looking ahead, what role do you believe Europe should play in the global future of advanced manufacturing? Are we moving fast enough, or is there more we must do to stay competitive and relevant?

Europe has a strong foundation — world-class research institutions, highly skilled talent, and a deep culture of engineering and innovation. But to stay competitive in advanced manufacturing, we need to move faster and think more collaboratively.

It’s not just about developing new technologies, but about scaling them — turning innovation into real industrial impact. That requires stronger partnerships between research, startups, and established companies, and a clear focus on speed, agility, and digitalization.

At the same time, we need to be brave enough to take risks and accept that not everything will work perfectly from the start. Innovation can only thrive when we allow room for experimentation — and yes, for failure. If we can foster that mindset across Europe, combining our strengths in quality, sustainability, and responsibility with courage and entrepreneurial spirit, we’ll not only stay relevant but lead the way in shaping the global future of advanced manufacturing.

Finally, what message would you share with young minds watching Future Port Youth who are curious, full of ideas and ready to make a difference?

Just go for it! Be brave, stay curious, stay open, and follow your heart. Don’t be afraid to take risks and explore your ideas — the world needs your creativity and energy.