The development of cutting tools today is not only driven by the demand for higher efficiency, but also by the rapid evolution of machinery, software, and materials. Innovations in microgeometry, new types of coatings, and advanced material grades are bringing tools into practice that increase productivity while reducing costs. Manufacturers such as Rotana are paying closer attention to customer feedback, enabling them to develop tools that minimize finishing operations, extend tool life, and improve surface quality.

Machinery and engineering have long been pillars of the Czech economy. According to the Czech Statistical Office, the industrial sector employs nearly 36% of the economically active population, putting the country at the top of the EU. In the Czech Republic, as elsewhere, developments in the engineering sector respond directly to pressing real-world demands, emerging technological trends, material innovations, and the ever-present need for maximum efficiency.

New Technologies and Materials

To keep pace with this accelerating transformation, toolmakers are focusing not only on digitizing and automating production processes but also on innovating tool design and applying new cutting material technologies. Achieving the final surface quality requires consideration of many parameters—including clamping, workpiece rigidity, and spindle clearances.

“Our goal is always to offer tools that help customers maximize productivity and reduce costs,” says Radek Švihálek, CEO of Rotana

It is precisely this willingness to listen—combined with deep process knowledge and state-of-the-art facilities—that allows the Czech-based tool manufacturer from Velké Meziříčí to successfully design, produce, and customize cutting tools.

Microgeometry Adjustments

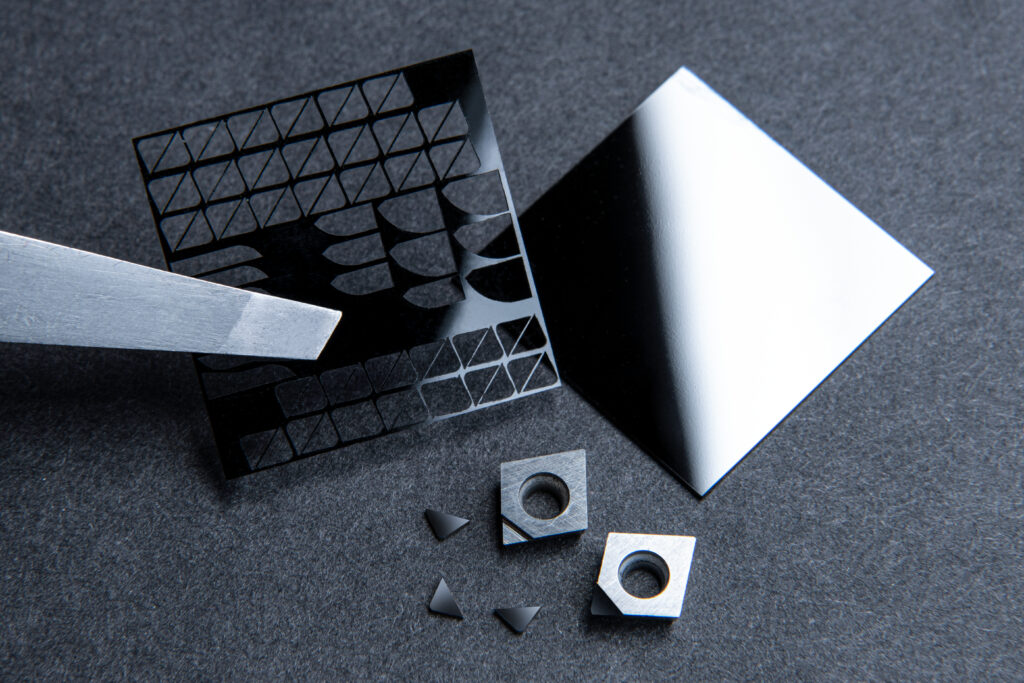

Rotana focuses on individualized solutions and uses a range of high-performance material grades in its tool production. Whether it’s cemented carbides or superhard materials, these grades cover a wide range of machined part properties. Notably, with CBN tools, Rotana has successfully developed solutions that eliminate the need for finishing operations—greatly increasing production efficiency for customers.

Another key factor influencing tool performance is the adjustment of cutting edge microgeometry. This directly affects edge stability, surface finish, and tool life. The most common types include sharp, rounded, and chamfered cutting edges, each with its own strengths and weaknesses. Ultimately, the microgeometry must be tailored to the application at hand.

“That’s the path we’ve taken,” confirms Pavel Smejkal, Head of Technical Production Planning.

“We’re using a newly implemented state-of-the-art dry electrochemical polishing technology.”

Compared to conventional methods, this technique delivers outstanding surface quality and integrity, significantly enhancing tool performance across a wide range of parameters.

The Advantage of Coatings

Among the many ways to improve cutting tool performance, coatings play a vital role. A major advantage for Czech manufacturers like Rotana is the availability of top-quality coating providers within the country. Choosing the right coating can significantly enhance a tool’s properties and extend its service life.

“Many of our clients have welcomed the fact that we introduced new, high-performance coatings last year,”

notes Jaroslav Vejrosta, Head of Sales at Rotana.

“They’ve seen the difference for themselves when comparing tools with these new coatings to what they previously used.”

One typical example is the RotX coating series, an efficient and versatile solution suited to a wide range of machining applications.

A Broad Selection of Modern Materials

Today’s tool manufacturing landscape includes a wide array of materials—cutting ceramics, tool steels, cemented carbides, cubic boron nitride (CBN), and synthetic diamonds. Each material offers a unique combination of properties, making material selection a critical factor when designing the right tool for a specific application.

Despite these material differences, the ultimate goal remains the same: to deliver tools that offer maximum productivity and help minimize production costs.

Source: Svět průmyslu Editorial Team

May 19, 2025